Shayna EcoUnified is an innovative company that uses new technology to help tackle plastic pollution in the environment, by turning plastic waste into affordable yet high performance structural materials, in the form of tiles and blocks.

About The Company

Shayna EcoUnified are the first and only company in India and SAARC countries to have the technology to produce these. This has been achieved in collaboration with the Council of Scientific Industrial Research (CSIR)- National Physical Laboratory’s (NPL), with whom this technology was developed, tested and certified for usage in multiple applications.

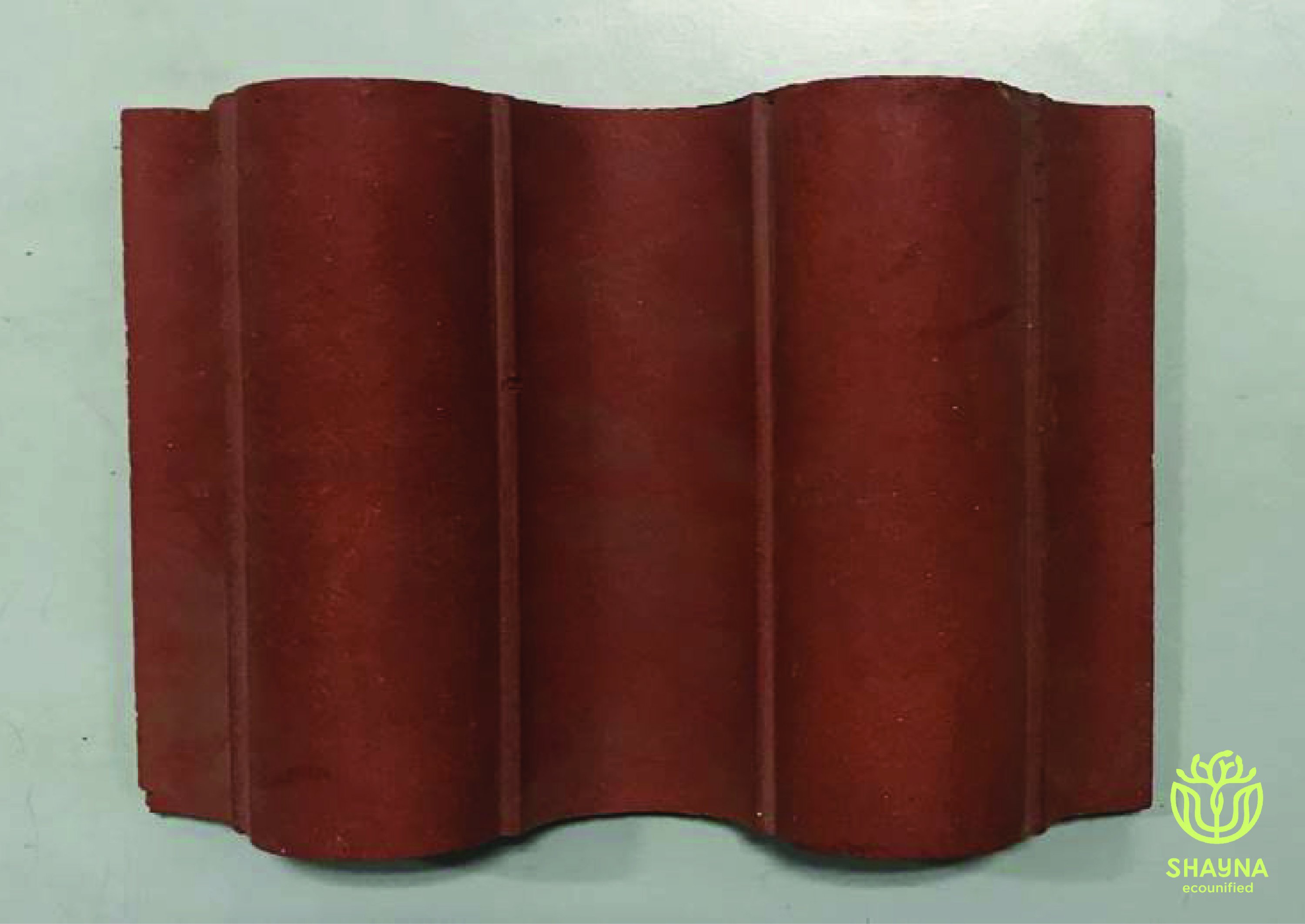

About The Product

The products have a range of qualities that have been successfully tested. For starters, they are incredibly durable; they are weather and heat resistant, acid and corrosion resistant, and chip resistant too. They are also hygenic, since they are both anti-bacterial and anti- microbial. Last but not least they are practical; they have anti- static and anti- skiding properties, and are ready to use with no drying required.

In summary, they offer better structural stability at a lower cost compared to conventional materials, as well as protecting the environment from plastic dumping. For example, 600 waste plastic bags are used to make one 12″ x 12″ tile weighing 900g. Each tile costs less than £1.

Uses

The tiles have a range of uses such as wall and floor tiles, pavement tiles and structures such as public toilets, shelters, park benches and guard rooms. They have recently been able to produce a prototype of a roof tile and will be starting the production of it in a few months.

Process

The entire process of production is 100 per cent eco- friendly. The types of waste plastic that will serve as the raw materials are PP (Polyproplyene), LDPE (Low density polythene), and HDPE (High density polythene). It will be processed at a controlled temperature to ensure no hazardous gases are emitted. Furthermore, all the stages of production is largely mechanical, further ensuring a safe and healthy environment.

Ethics

Shayna EcoUnified are about to start fully fledged production in the next few weeks. The prototypes have been made by daily wage workers who they are hiring on full- time basis starting next month. The production site is adequately sized, the machine-run production area is covered, whilst the rest is open and full of greenery.

There are essential facilities provided on-site for labours, and filtered drinking water supply maintained. Health and safety measures are currently being installed. Also, they will be conducting training and capacity building sessions for women.

Distribution

Once they become established in the Indian domestic market and are able to deliver maximum output, they plan to sell the product in other countries as well.

Find out more about Shayna EcoUnified on their website, twitter or facebook.

Is cement and sand are need for this tiles

Kindly mail the product details on mail I’d —– mk3interior@gmail

Thankx….